MACHINE MECHANICAL WORKING

Home / MACHINE MECHANICAL WORKING

PRECISION AND PRODUCTIVITY

EXPERTISE AND SECTORS OF APPLICATION

We process monolithic products up to 600 kg with the help of the best technologies that the market can offer today.

We carry out coatings in F51 Inconel 718-625-F316, we have certified welders and assembly personnel, and we are available to travel throughout Italy and abroad.

Over the years, our know-how has enabled us to carry out work in various sectors, like:

- Medical

- Food

- Petrochemical

- Hydraulic

- Automotive

From drawings to project, from idea to results

CAD/ CAM software allow us to:

- Develop customized application based on inquiries

- Support and modify existing components and application

- Prototyping

For Design and development we use:

- CAD PTC Creo Elements Direct Modeling

- CAM Go2Cam.

Our softwares can process IGES, STEP, DWG, DXF files.

Multiple components, one process

No manual intervention is required till the end of the process.

Parts programming is carried out using a CAM system. With the help of a post processor, the previously created 3D mathematics are transformed into machine language.

The program is transmitted by ISDN line to the machine CNC.

ADVANTAGES OF MECHANICAL MACHINING

The high level of precision and flexibility allows complex operations with stringent requirements in terms of tolerance, surface finishing, quality and speed.

- Parts up to 600 mm diameter and 400 mm high with a maximum weight of 600 kg

- Prototype production and development

- Series production

- High precision

- Excellent quality and finishing

- Multi-processing

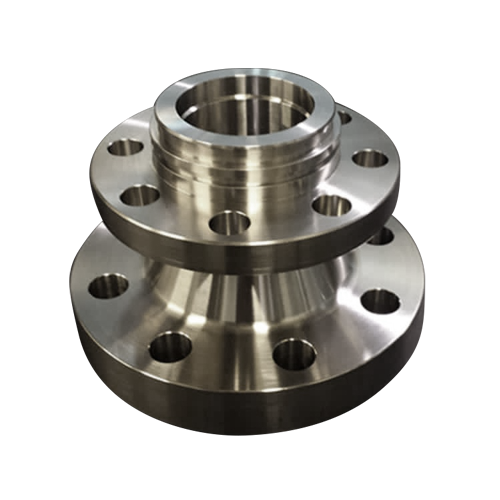

OUR PRODUCTS

BUSINESS AREA

Our working station

Wele 1565 working station

- X : 1300 mm

- Y : 650 mm

- Z : 600 mm

- 3 axes mm 250

Wele 1365 working station

- X : 1500 mm

- Y : 650 mm

- Z : 600 mm

- 4 axes mm 350

Leadwell MCV 1000CR working station

- X : 1000 mm

- Y : 650 mm

- Z : 600 mm

- 4 axes mm 250

Kitamura HX400 IF working station

- 2 Pallet 500×500

- X: 740

- Y: 650

- Z: 800

Fagima – FA12/60 working station

- X: 1600

- Y: 600

- Z: 600

Doosan lathe Puma 300 – N.2

- Axis X : 300 mm

- Axis Z : 680 mm

- Turning diameter 500 mm

Kia lathe 21 LMS Motorized

- Axis X : 300 mm

- Axis Z : 680 mm

- Axis C : 360° Turning diam: 400 mm

CN – CMT – URSUSTC600 Lathe

- Turning diameter 355 mm

- Bar passage Ø 105 mm

CN – CMT – URSUS PLUS250 Lathe

- Turning diameter 260 mm

- Bar passage Ø 50 mm

PUMA 400ML Lathe

- Axis X: 560 mm

- Axis Z: 2150 mm CNC rest, motorized

Manual lathe – Graziano

- Turning diameter 350 mm

- Bar passage Ø 50 mm

Friggi hacksaw – 1MF320CN

- Maximum diameter. 300 mm

Pedrazzoli hacksaw – BROWN SN270

- Maximum diameter. 210 mm

Pfauter gear cutting machine

- Straight gear shaping and fitting

- External

- Ø 220 mm

- L: 400 mm

Three-dimensional machine

- DEA Gamma 102

- Axis X : 1000 mm

- Axis Y : 500 mm

- Axis Z : 400 mm

- Head: Renishaw PH 9 Mechanical

Correa – Standard milling cutter - F2VE – N.2

- X: 1200

- Y: 450

- Z: 500

CAMS slotting machine – 200

- Vertical stroke 200 mm